Foster Induction Private Limited is the major Induction Annealing System Manufacturers in Gujarat. Annealing is a form of heat treatment where a metal or alloy reaches a certain temperature value, where holding time and subsequently cooling the metal to room temperature slows down its heat. By following this procedure, the internal or microstructure will be altered such that the mechanical and physical aspects of the said material are enhanced. The induction annealing procedure achieves the specified task with the use of electromagnetic induction, allowing for correct, focused temperature rise by means of non-contact and controlled methodology. Besides, our systems also guarantee a clean and safe process-not involving flame, chemicals, or external burners-which leads to a safe, emission-free working environment. Besides, our induction systems are friendly to the environment and can help an industry with plans to reduce its carbon footprint while it aims efficiently to carry out a heat treatment process.

We are the Customized Induction Annealing System in Rajkot. The features that are considered important in our systems are control and automation. Equipped with instinctive control interfaces, operators could intuitively adjust the heating parameters, setting temperature, duration, and power output with precision. Such a form of control means that industrial users can gain custom annealing profiles for material composition, size, and requirements that differ. Our induction annealing systems also come with an assortment of added advantages over prior annealing methods. Undeniably, one of the biggest advantages that the use of induction annealing technology offers is a precision heating concept. The process delivers heat only to the specific areas required, ensuring uniform heating without adverse effects on the rest of the component. This is where the consistency and repeatability come in, making our systems ideal for industries that demand high-quality material processing.

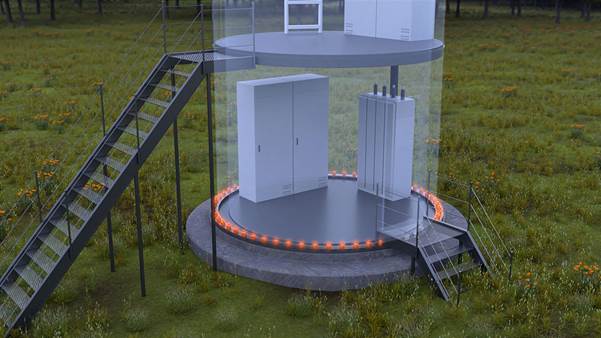

Choose us for all the needs of your Induction Annealing System Exporters and Suppliers in India. We equip our systems with advanced power supplies that can fine-tune frequencies and power output to accommodate a wide range of material types and annealing requirements. Be it thin wires, small metal parts, or larger components, the heat delivered by our systems is just what is required without any wastage or overheating. Overheating during long periods of operation is prevented by the cooling mechanisms integrated into our systems, thus ensuring long-term operational safety and performance. Intuitive and user-friendly, the interface allows operators to easily program, monitor, and adjust parameters for reliable results every cycle. Our systems are designed for stand-alone operation and can also be seamlessly integrated into existing production lines. Our versatile and scalable systems can be tailored to meet the needs of any operation.